VANDENBERG SPACE FORCE BASE, CA – Proteus Space has successfully launched its first spacecraft, MERCURY ONE, setting a new industry benchmark for rapid development. The company confirmed it took the satellite from a blank-sheet design to a launch-ready vehicle in only nine months, a timeline enabled by its proprietary AI-driven engineering platform.

The mission, which lifted off from Vandenberg Space Force Base on November 28, 2025, validates the company's MERCURY™ platform and demonstrates a significant acceleration in the satellite manufacturing lifecycle, which traditionally takes years.

Key Takeaways

- Proteus Space successfully launched its MERCURY ONE satellite, achieving first contact shortly after.

- The spacecraft was designed and built in a record nine months, a fraction of the typical industry timeline.

- The mission was enabled by MERCURY™, an AI-powered platform that automates and optimizes satellite design.

- One payload partner was able to add their hardware just seven months before launch, demonstrating the system's flexibility.

- The company plans to offer its MERCURY™ platform as a Software-as-a-Service (SaaS) product by the end of 2026.

A New Benchmark for Satellite Development

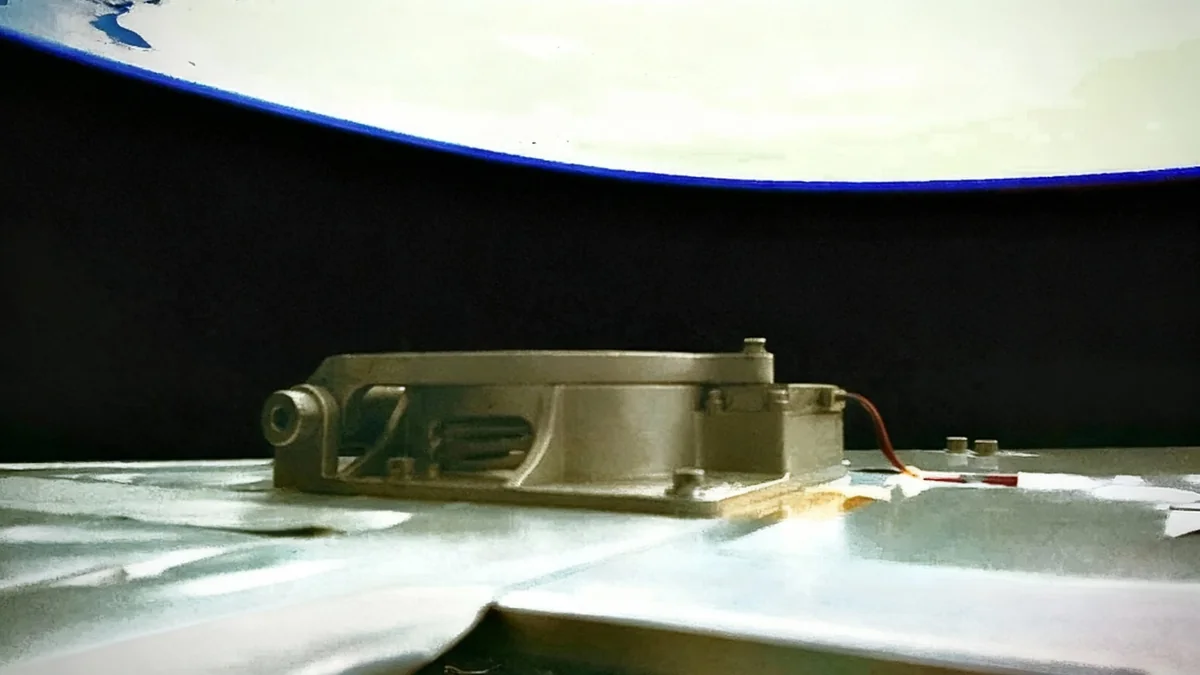

The successful launch of MERCURY ONE represents a major milestone for Proteus Space and the broader aerospace industry. Completing an ESPA-class satellite, which carried four distinct payloads, in just nine months is a significant departure from conventional development cycles.

Company officials stated that Proteus Space managed the entire process internally, including the initial design, assembly, integration, testing, and launch operations. This vertical integration, combined with their rapid design technology, allowed for an unprecedented pace.

“Twelve months ago we had no mature design, no payloads and no metal in house for this first of its kind, ESPA class, four payload spacecraft,” said David Kervin, CEO of Proteus Space. “Think about that. It’s a huge testament to what technology enabled humans can do with our MERCURY™ platform.”

Kervin emphasized that this achievement was accomplished with only seed-stage capital and funding from the Small Business Innovation Research (SBIR) program, highlighting the efficiency of their approach.

What is an ESPA-Class Satellite?

ESPA, or EELV Secondary Payload Adapter, refers to a standardized ring used on rockets to mount multiple smaller satellites. An ESPA-class satellite is designed to fit this standard, often serving as a rideshare bus carrying several smaller payloads for different customers on a single launch, which helps reduce costs.

The Technology Behind the Speed

At the core of this achievement is the company's MERCURY™ platform. Described as an AI-enabled, rapid concurrent engineering system, it automates many of the complex and time-consuming tasks involved in designing a satellite. The platform rapidly generates payload-tailored and mission-optimized designs, eliminating traditional bottlenecks.

By leveraging advanced algorithms, MERCURY™ can produce non-proprietary, vendor-agnostic design definitions. This is a critical feature, as it frees customers from being locked into a single hardware supplier, which can cause delays and increase costs.

The system compresses a process that typically takes years into a matter of months. According to Proteus Space, the platform delivers complete design packages that are validated using Hardware-in-the-Loop (HIL) simulations, ensuring the designs are viable for manufacturing before any metal is cut.

Unprecedented Flexibility for Payload Partners

The MERCURY ONE mission carried payloads for several collaborators, including NASA’s Jet Propulsion Laboratory, UC Davis, and Leonardo DRS. A key demonstration of the platform's agility involved the integration of the Leonardo DRS payload.

In a move considered nearly impossible with traditional methods, Leonardo DRS was able to add its radio payload to the spacecraft *after* the Preliminary Design Review (PDR) was already completed. This late addition occurred just seven months before the scheduled launch and did not cause any delays or require a major redesign of the satellite bus.

Late-Stage Integration

The ability to add a major piece of hardware like a radio payload post-PDR without impacting the schedule showcases extreme design flexibility. In conventional satellite projects, such a change would typically trigger months of redesign and analysis, leading to significant delays and cost overruns.

John Corbean, a Vice President at Leonardo DRS, commented on the experience.

“Integrating our payload onto the MERCURY ONE bus after PDR, without any schedule impacts or major bus redesigns, demonstrates the unique advantages of this innovative approach,” Corbean stated. He added that the platform’s responsiveness allowed his company to accelerate the critical on-orbit testing of its technology to meet market timelines.

Future Implications for the Space Industry

The success of MERCURY ONE serves as flight heritage for the MERCURY™ platform, elevating its Technology Readiness Level to TRL9—the highest level of technological maturity. This validation paves the way for wider adoption.

Proteus Space has announced plans to commercialize its core technology. The company intends to offer a beta version of the MERCURY™ platform as a Software-as-a-Service (SaaS) product to both commercial and government customers by the end of 2026.

CEO David Kervin described this upcoming release as a “watershed event in the space industry.” By providing rapid, on-demand satellite design capabilities, the platform could fundamentally change how space assets are developed and deployed, enabling what the company calls “elastic space capacity.” This would allow organizations to respond to needs and opportunities in space on radically shorter timelines than ever before.