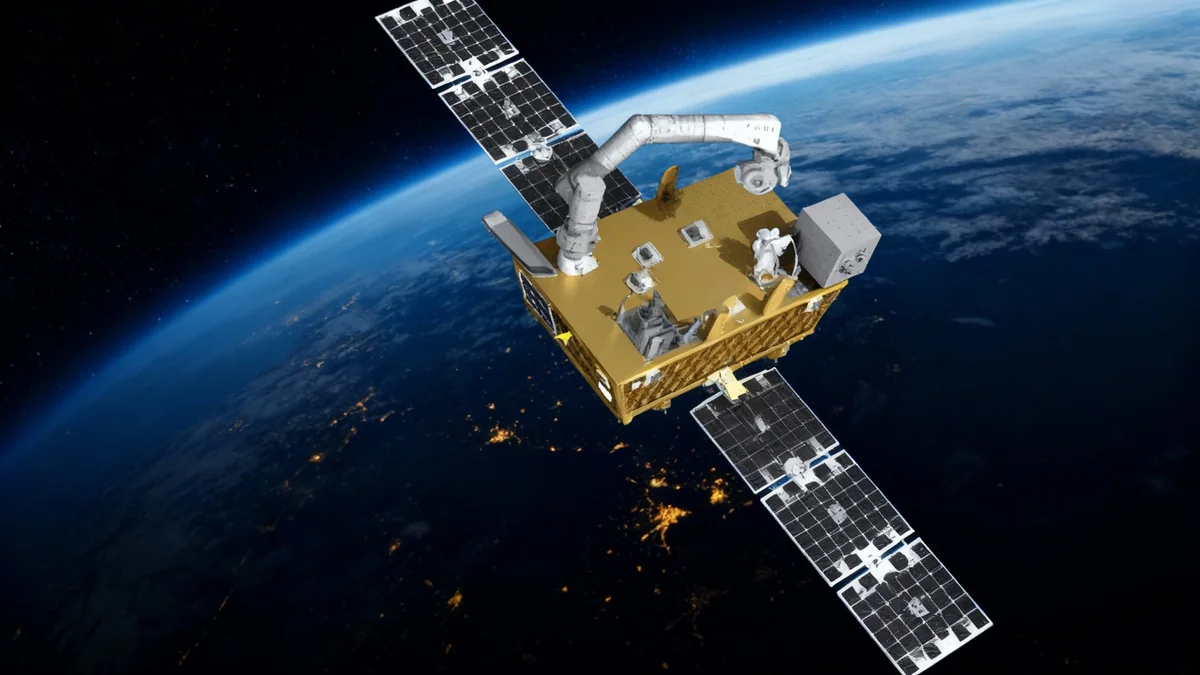

NASA is partnering with commercial companies for a mission set to launch in late 2027, aiming to test a sophisticated robotic arm in low Earth orbit. The project, named Fly Foundational Robots (FFR), is a key step toward developing the technologies needed for building and maintaining infrastructure in space, including on the Moon and Mars.

This demonstration will validate capabilities crucial for future long-duration missions, such as assembling structures, servicing satellites, and assisting astronauts far from Earth. The mission represents a significant investment in the growing commercial space industry and the future of in-space manufacturing.

Key Takeaways

- NASA's Fly Foundational Robots (FFR) mission will launch in late 2027 to test a commercial robotic arm in space.

- The arm, developed by Motiv Space Systems, can manipulate tools and move across spacecraft exteriors.

- The mission is a collaboration with private firms, including Astro Digital, which will provide the host spacecraft.

- This technology is essential for future goals like satellite refueling, lunar habitat construction, and in-space assembly.

A New Era of Construction in Space

The core of the FFR mission is to prove that complex robotic tasks, currently performed on Earth, can be replicated in the challenging environment of space. The robotic arm at the center of this test is not just a simple crane; it is designed for dexterous manipulation and autonomous operation.

Developed by Motiv Space Systems, a California-based small business, the arm is engineered to use various tools and even "walk" across the exterior of a spacecraft. This mobility is a critical feature for future applications, allowing a single robotic system to perform maintenance and assembly tasks across a large area without needing to be repositioned by another system.

The mission will be hosted on a spacecraft provided by Astro Digital. This partnership model, where NASA contracts with commercial providers for launch and operational services, is part of a broader strategy to foster a robust and competitive American space industry.

What is ISAM?

ISAM stands for In-space Servicing, Assembly, and Manufacturing. It refers to a suite of technologies that allow for the construction, repair, and modification of spacecraft and structures directly in orbit. This capability is seen as essential for reducing the cost of space missions and enabling more ambitious exploration goals, as it avoids the need to launch large, fully assembled structures from Earth.

The Technology Behind the Mission

The robotic arm from Motiv Space Systems is the result of a NASA Small Business Innovation Research (SBIR) award, a program designed to help small companies develop technologies that meet federal research and development needs.

Capabilities of the Robotic Arm

- Dexterous Manipulation: The ability to handle delicate components and complex tools with precision.

- Autonomous Tool Use: The arm can operate independently to complete pre-programmed tasks without constant human intervention.

- External Mobility: A unique "walking" function allows it to move across a spacecraft's structure, expanding its operational reach.

- Zero-Gravity Adaptation: Engineered to function effectively in both zero and partial gravity environments, like those on the Moon or Mars.

These capabilities will be tested through a series of demonstrations once the FFR mission reaches orbit. NASA will act as the first guest operator, putting the arm through its paces. The agency is also inviting other U.S. partners to propose experiments, effectively turning the mission into an open testbed for in-space robotics.

"Today it’s a robotic arm demonstration, but one day these same technologies could be assembling solar arrays, refueling satellites, constructing lunar habitats, or manufacturing products that benefit life on Earth," stated Bo Naasz, a senior technical lead for ISAM at NASA Headquarters.

Building the Future Space Economy

Beyond the immediate technical goals, the FFR mission is a strategic investment in the future of space exploration and commerce. By proving these robotic capabilities, NASA aims to de-risk the technology for commercial companies, encouraging further private investment in the sector.

Mission Partners

- NASA: Manages the mission through its Space Technology Mission Directorate and Goddard Space Flight Center.

- Motiv Space Systems: Supplies the advanced robotic arm system.

- Astro Digital: Provides the host spacecraft and orbital testing services.

The long-term vision is an ecosystem where robots handle routine construction and maintenance in orbit. This would free up astronauts to focus on scientific research and exploration. Such infrastructure could one day support satellite refueling depots, large-scale space telescopes assembled in orbit, and permanent habitats on other celestial bodies.

As Naasz explained, this is how a sustainable human presence beyond Earth is built. "This is how we build a dominant space economy and sustained human presence on the Moon and Mars," he said. The applications could also have a significant impact back on Earth, with advancements in robotics potentially benefiting industries like construction, medicine, and transportation.

What Comes Next

The FFR mission is a foundational step. Its success will pave the way for more complex and ambitious ISAM missions in the coming decade. Data gathered from the 2027 demonstration will inform the design of next-generation robotic systems for NASA's Artemis program and future missions to Mars.

Testing these systems in low Earth orbit provides a relatively safe and accessible environment before they are deployed to more distant and challenging destinations. The mission serves as a critical bridge between concepts developed on the ground and the practical realities of working and building in space.