A robotic system developed by the U.S. Naval Research Laboratory (NRL) has successfully completed a critical series of tests that simulate the harsh conditions of space. This technology is designed to inspect, repair, and upgrade satellites while they are in geosynchronous orbit, potentially extending their operational lifespans and reducing long-term costs.

The system, known as the Robotic Servicing of Geosynchronous Satellites (RSGS) payload, was tested while integrated with Northrop Grumman's Mission Robotic Vehicle (MRV) spacecraft. The successful completion of this thermal vacuum testing marks a significant step toward the system's eventual launch and on-orbit deployment.

Key Takeaways

- The US Naval Research Laboratory's RSGS robotic system successfully passed space-readiness testing.

- The tests simulated the extreme temperatures and vacuum of geosynchronous orbit, approximately 36,000 kilometers above Earth.

- Developed with Northrop Grumman and DARPA, the system aims to service, repair, and upgrade satellites directly in orbit.

- The technology features two robotic arms, advanced sensors, and various tools for complex on-orbit tasks.

- Following these tests, the system will undergo final integration before its planned launch.

A New Era for Satellite Maintenance

The successful test marks the culmination of more than two decades of dedicated research and development by the NRL. The project, a collaboration with Northrop Grumman’s SpaceLogistics and supported by funding from the Defense Advanced Research Projects Agency (DARPA), is poised to change how satellites are managed in space.

During the recent milestone, the combined RSGS-MRV spacecraft was placed inside a specialized thermal vacuum (TVAC) chamber. This facility subjected the hardware to the punishing environment it will face in orbit, including extreme heat, intense cold, and a near-perfect vacuum. The test confirmed the system's durability and operational readiness.

"This is more than a successful test, we are nearing the culmination of decades of work and partnership that began as a vision for on-orbit servicing and it’s exciting to be so close to this technology being space-qualified and ready for flight," stated Bernard Kelm, acting director of the Naval Center for Space Technology.

The ability to service satellites in orbit could fundamentally alter space operations for both military and commercial sectors.

Addressing Challenges in Geosynchronous Orbit

Hundreds of critical satellites operate in geosynchronous orbit, located approximately 22,000 miles (36,000 kilometers) above the Earth's surface. At this altitude, satellites match the Earth's rotation, allowing them to remain over a fixed point on the ground, which is vital for communications and surveillance.

What is Geosynchronous Orbit?

Geosynchronous Earth Orbit (GEO) is a high Earth orbit that allows satellites to match Earth's rotation. An object in such an orbit has an orbital period equal to the Earth's rotational period (one sidereal day), and thus appears motionless, at a fixed position in the sky, to ground observers. This is crucial for telecommunications, broadcasting, and weather satellites.

However, this remote location makes any form of physical maintenance impossible with current technology. If a satellite malfunctions or its technology becomes outdated, it is often abandoned. To mitigate this, satellites are currently built with heavy, expensive backup systems and carry extra fuel, increasing launch costs and complexity.

The NRL-developed robotic servicing technology is designed to overcome these limitations. It will enable missions to perform close-up inspections, make orbital adjustments, repair malfunctioning components, and even install hardware upgrades on existing satellites.

Advanced Robotic Capabilities

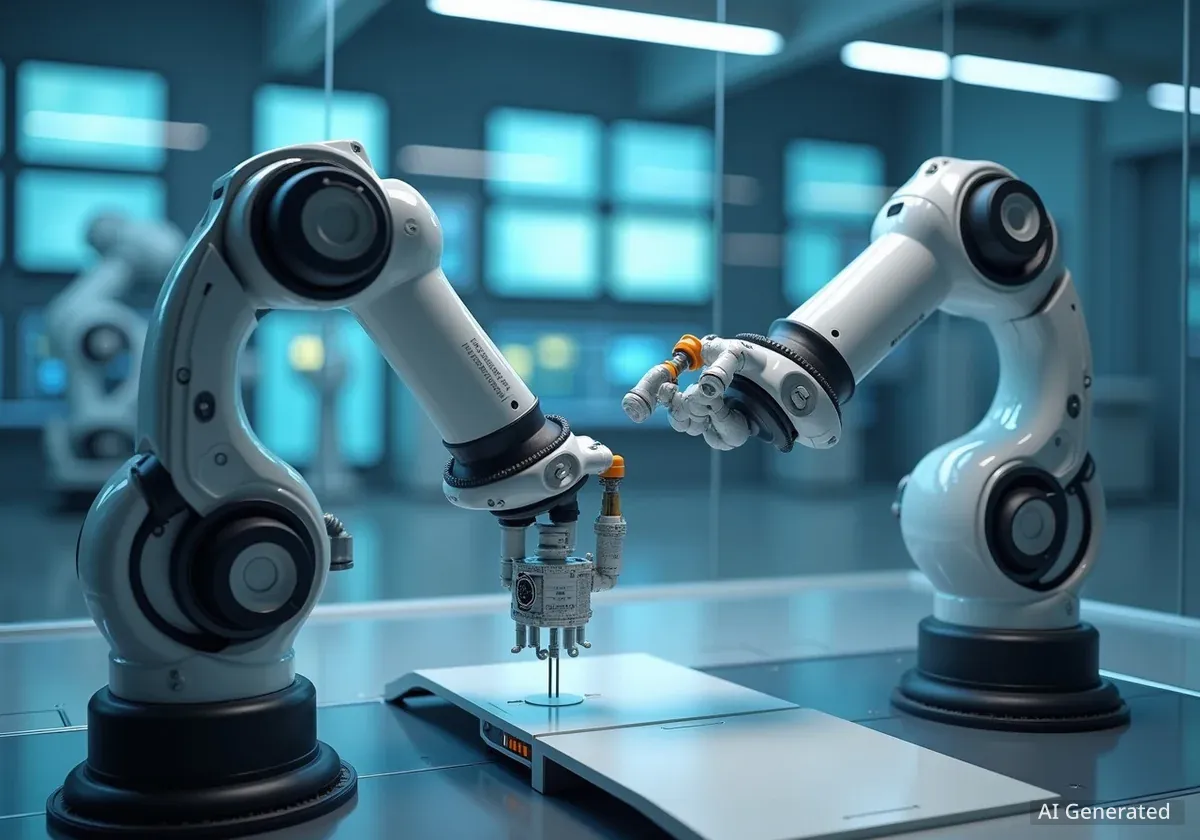

The RSGS system is a highly sophisticated piece of engineering equipped for complex tasks in a zero-gravity environment. Its primary features are designed for precision and safety during Rendezvous and Proximity Operations (RPO).

Core Components of the RSGS Payload

The system's design includes several key elements that allow it to interact safely with other spacecraft:

- Dual Robotic Arms: The payload features two dexterous robotic arms capable of performing delicate operations like capturing, inspecting, and manipulating satellite components.

- Advanced Avionics: A sophisticated control system manages the robotic arms and processes data from the sensor suite.

- Comprehensive Sensor Suite: The system is equipped with a range of cameras, infrared imaging devices, and other sensors to safely approach and analyze client satellites without physical contact.

- Modular Tool System: The robotic arms can be fitted with a variety of specialized tools for different tasks, with the potential to add new tools in the future as mission requirements evolve.

A Long-Term Vision

The concept of on-orbit satellite servicing has been a goal for space agencies for decades. The successful ground testing of the RSGS-MRV system represents one of the most significant advancements toward making this concept a practical reality for both government and commercial satellite operators.

According to the NRL, this technology will enable routine in-orbit servicing, which is expected to lead to longer satellite lifespans, reduced operational costs, and new opportunities for technological innovation in space.

"The completion of spacecraft thermal vacuum testing marks the most critical milestone of recognizing that the NRL-developed payload and MRV are capable of working together as a system," said Dr. Bruce Danly, NRL Director of Research.

Path to Launch and On-Orbit Operations

The rigorous TVAC testing was completed on September 5 at the NRL's Naval Center for Space Technology (NCST) in Washington, D.C. With this phase concluded, the integrated RSGS-MRV system is scheduled to be transported to a Northrop Grumman facility in Virginia. There, it will undergo the final round of integrated systems testing to ensure all components work together seamlessly.

Once the spacecraft is launched and reaches its designated orbit, it will enter an initial checkout phase. During this period, ground controllers will verify that all systems are functioning correctly after the stresses of launch.

Following the checkout, the system will commence a series of on-orbit demonstrations. These will validate its core capabilities, including:

- Rendezvous Maneuvers: Safely approaching other objects in orbit.

- Proximity Operations: Maintaining a stable position near a client satellite.

- Client Servicing Tasks: Performing simulated tasks such as inspections, anomaly resolution, and orbital adjustments.

These demonstrations are crucial for proving the system's effectiveness and reliability before it begins operational missions. "With launch preparations starting soon, RSGS is poised to demonstrate its robotic capabilities in orbit for the first time, marking the beginning of a new era in resilient space operations," the NRL noted in a press release. While an exact launch date has not been announced, it is anticipated to occur in the coming years.